The DLC Series water leak detection cable consists of 1/4” diameter, 4 wire, insulated bundle. It is available in two pre-packaged lengths of 50’ and 100’. The cable assembly has factory installed connectors making it easy to connect consecutive sections to achieve the desired length. The DLC cable is very strong and can be pulled into place with- out the risk of damage. The orange color makes it easy to locate in difficult-to-see areas. The special insulation allows the cable to produce accurate distance readings, regardless of conductivity of the fluid. Even distilled water will produce an alarm. This special coating, when combined with AquaALERT’s traditional AC supervision, virtually eliminates galvanic corrosion (electrolysis). The DLC Series Cable is available in both 50′ and 100′ rolls for your convenience.

Routing

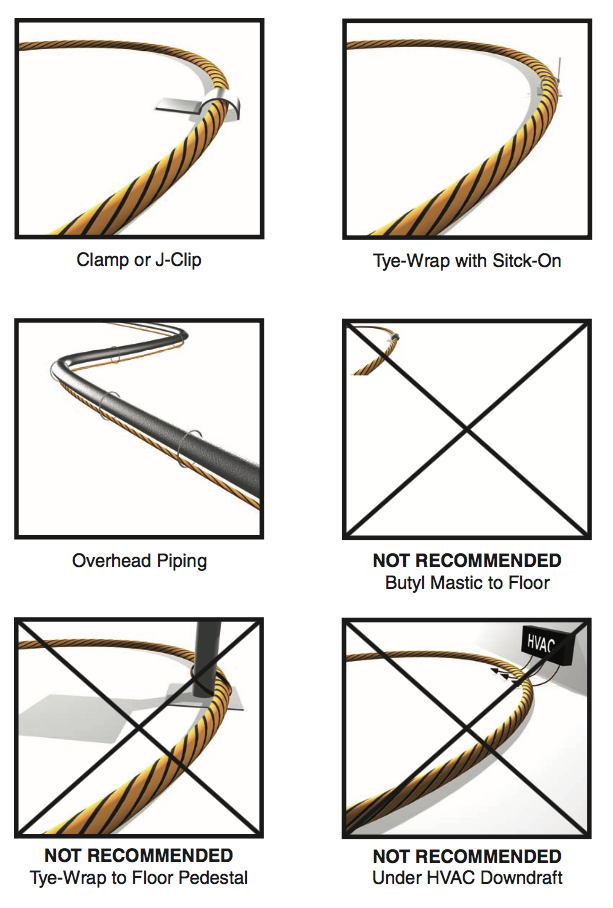

For the cable to be effective, it must come in contact with the leaking water. Route the cable around -or adjacent to- the likely source of potential leakage. Use the cable as a barrier between the source of a leak and the protected area. Make sure to maintain at least six feet from any HVAC downdraft. Water droplets from the cooling coils as well as moisture from the humidifiers can cause false alarms. When there are many sources for potential leakage, consider arranging the cable in a “serpentine” pattern. Starting at the DLS annunciator, wind the cable back and forth, spacing each run 5’ to 10’ apart, ending on the other side of the room.

Installing The Cable

Keep the cable rolled-up until ready to install. Do NOT allow the cable to become kinked as it is pulled into place. Secure the cable to the floor using self-stick cable clamps every five feet. Add sections of cable as required for total length. Use a cable on each side of the connectors, leaving a little slack for future service. Install the EOL device at the end of the last section.

Recommended Installation Methods